Our Process:

Powder Coating in Wyoming & Chisago County, MN

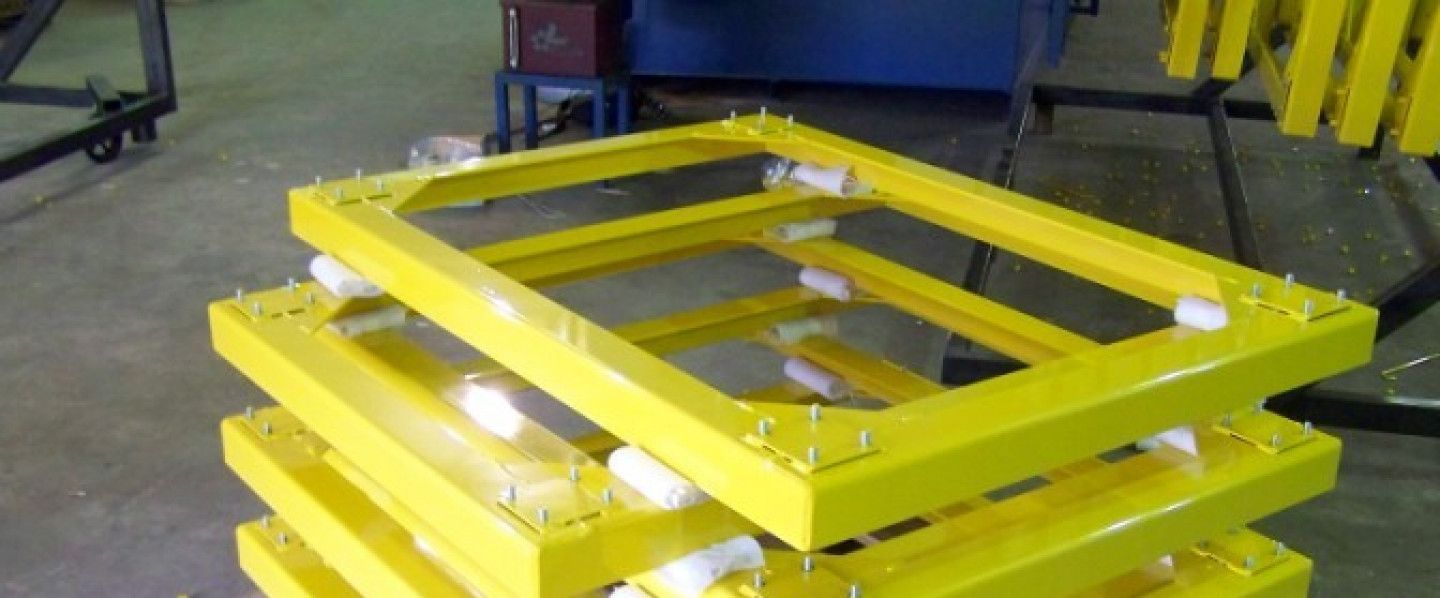

Our process starts with the very first phone call or email. We will assist you with what type of powder is best for your application. Once the desired powder is selected, the process can begin.

After receiving the items, we stage them in order of color and curing temperatures. Once staged, the items get hung on our conveyor line. The conveyor brings the items into our 5-stage wash where they get cleaned, rinsed and coated to resist corrosion. This process prepares substrate for powder.

Our Process

1. Pre-Treatment & Cleaning

Parts are washed, prepped, and inspected before coating.

2. Powder Application

Electrostatic application ensures even coating and strong adhesion

3. Curing

Parts are cured to manufacturer specifications for durability.

4. Inspection & Quality Control

Final inspection verifies mil thickness, coverage and surface appearance

1

Pre-Treatment & Cleaning

Wash • Prep • Inspect

Parts are thoroughly cleaned using water and detergents to remove oils, dirt, and contaminants—creating the proper surface for coating adhesion.

2

Powder Application

Electrostatic Coating

Powder is electrostatically applied, allowing it to cling evenly to the grounded part for smooth, consistent coverage.

3

Curing

Heat Activated Durability

Parts move into the curing oven, where heat melts and fuses the powder into a tough, long-lasting finish.

4

Inspection & Quality Control

Verified Before It Ships

Each part is inspected for mil thickness, coverage, and surface appearance to ensure it meets our quality standards.

Our Facility Features:

20,000 Sq. Ft. of Space

120 Foot Oven

Accommodating 3 Ft. x 5 Ft. x 16 Ft.

Stage Chemical Process

Vast Array Of House Powders

Inventory/Shipment Management

Request More Information:

Contact Us

We will get back to you as soon as possible.

Please try again later.